Hey there! Ever wondered why some medicines seem to disappear into your bloodstream like a secret agent, delivering their payload exactly where it’s needed, while others just wander around causing unwanted side effects? The answer might lie in a tiny, but mighty technology called programmable microcapsules. Think of them as miniature, smart “gift boxes” that know when, where, and how to open themselves. In this post we’ll walk through what makes these capsules so special, how they could change the way we get vaccinated, and why you should feel excited (and a little reassured) about the future of drug delivery.

Why Programmable Matters

What Are Programmable Microcapsules?

At their core, programmable microcapsules are microscopic spheres—typically from a few micrometers to a few hundred micrometers in diameter—containing a drug, vaccine, or any biomolecule you can imagine. What sets them apart is the “program” built into their shell: a built‑in trigger that responds to temperature, pH, enzymes, magnetic fields, or even light. When the right cue arrives, the shell bursts or becomes permeable, releasing the cargo right on cue.

How Do They Achieve On‑Demand Release?

Imagine a waxy shell that stays solid at room temperature but melts when it reaches 50 °C, or a hydrogel that swells dramatically when it encounters the acidic environment of the stomach. Researchers have demonstrated both approaches. For example, a study in responsive capsules that enable hermetic encapsulation and thermally triggered burst‑release showed how a wax‑based shell can keep a drug sealed for weeks, then burst cleanly when heated.

What Problems Do They Solve?

Traditional pills or injections spread their contents throughout the body, which can lead to off‑target effects and the need for higher doses. Programmable microcapsules keep the payload locked until it reaches the right spot—whether that’s a tumor, an inflamed gut, or a vaccine‑responsive immune cell—dramatically improving efficacy and slashing side‑effects.

Clinical Applications

Single‑Shot Vaccines

One of the most thrilling possibilities is a single shot vaccine that eliminates the need for boosters. By loading a capsule with both the primary antigen and a “second‑wave” booster that only releases months later, scientists can give you a one‑time jab that keeps you protected for years.

Malaria Vaccine Delivery

Malaria thrives in hot, humid regions where keeping vaccines cold is a nightmare. Programmable capsules made from waxes with a defined melting point can survive high temperatures, then melt once they reach body temperature, delivering the antigen safely. Check out the malaria vaccine delivery page for a deeper dive on how this works on the ground.

Booster‑Shot Alternative

Imagine a capsule that senses when your antibody levels dip and releases a booster dose automatically. Researchers are already modeling this “smart booster” concept, showing that a pH‑responsive hydrogel could release a secondary antigen once the body’s immune signaling changes. It’s like having a tiny medical assistant living inside you.

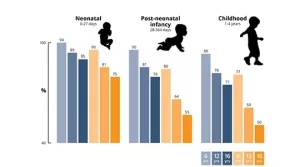

Boosting Immunization Coverage

In many low‑resource settings, repeated clinic visits are a major barrier to high immunization coverage. A single, heat‑stable capsule that can be administered once and then self‑activate when needed could dramatically raise coverage rates, especially in remote areas where cold‑chain logistics are a challenge.

Design Principles

Material Choices

Choosing the right shell material is the heart of the design. Common options include:

- Alkane waxes – provide a precise melting temperature.

- PDMS/TMPTMA blends – give tunable mechanical strength and controlled fragmentation (see tunable mechanical properties of PDMS–TMPTMA microcapsules).

- pH‑responsive hydrogels derived from methacrylic anhydride – swell in acidic environments such as inflamed tissue.

Programming the Release

Scientists can “write” instructions into the capsule by pairing mechanical cues (shell thickness, brittleness) with chemical cues (trigger molecules, catalytic sites). A 2007 Soft Matter paper introduced the idea of an “instruction set” that couples these cues, letting the capsule decide when to burst based on its surroundings.

Safety & Biodegradability

After delivering their cargo, capsules should safely dissolve or be cleared. Biodegradable polymers like PLGA, or fully bio‑compatible waxes, ensure that any leftover shell fragments pose minimal risk.

Design Checklist

| Parameter | Typical Range | Effect on Release | Recommended Test |

|---|---|---|---|

| Shell melting temp (Tm) | 45–65 °C (alkane wax) | Thermal burst | DSC analysis |

| PDMS:TMPTMA ratio | 20:80–30:70 | Shell fragility / debris size | Compression test |

| Hydrogel pKa | 4.5–6.5 | pH‑triggered swelling | Swelling kinetics |

| Core particle size | 0.5–10 µm | Diffusion barrier | Microscopy |

Manufacturing Strategies

Microfluidic Double‑Emulsion Templating

This technique creates a water‑in‑oil‑in‑water droplet that becomes the capsule. By tweaking flow rates and adding a co‑solvent like ethyl acetate, you can steer the capsule from a simple core‑shell shape to a “rattle” structure. A 2025 Nature Communications article walked through exactly how this works, showing that larger droplets and slower continuous‑phase flow favor multi‑layered capsules.

3D‑Printed Release Capsules

In 2015, a Nano Letters team demonstrated that you can 3‑D print polymer shells with built‑in channels for precise burst timing. This approach is especially promising for personalized medicine, where a doctor could print a capsule tailored to a patient’s unique physiology.

Scale‑Up Options

For commercial production, spray‑drying or high‑shear emulsification can generate millions of capsules per hour. The key is to keep the trigger chemistry intact—some labs add a protective “core‑shell” carrier during spray‑drying to avoid premature activation.

Process Optimization Flowchart (conceptual)

1️⃣ Choose material → 2️⃣ Set trigger parameters → 3️⃣ Select manufacturing route (microfluidic vs. 3‑D printing) → 4️⃣ Validate release kinetics → 5️⃣ Scale‑up and quality control.

Regulatory & Ethical Considerations

Pathways to Approval

Programmable microcapsules fall under the “drug‑device combination product” category in the U.S. and the EU. This means you need both a safety dossier (toxicology, biocompatibility) and a performance dossier (release profiles, efficacy). The FDA’s guidance on combination products (2024) outlines a step‑by‑step submission process.

Risk‑Benefit Balance

While the benefits are clear—higher efficacy, lower dose, fewer clinic visits—there are still unknowns about long‑term shell residues. That’s why pre‑clinical studies focus heavily on clearance pathways and any potential immune reactions to the capsule materials.

Transparency to Patients

When you get a vaccine that uses a programmable capsule, you deserve to know that the “burst” is triggered by your body’s own signals, not by a hidden chemical. Clear labeling and informed‑consent materials are essential to build trust.

Regulatory Submission Checklist

| Item | Documentation Needed |

|---|---|

| Material safety data | SDS, toxicology reports |

| Release kinetics | In‑vitro and in‑vivo data |

| Manufacturing SOPs | Batch records, QC metrics |

| Clinical protocol | Phase I/II design |

Future Outlook

Smart Immune‑Modulating Capsules

Imagine capsules that can talk to your immune system: they sense cytokine levels and release small‑molecule adjuvants only when needed. Combine that with AI‑driven dosing algorithms, and you have a truly personalized vaccine platform.

Multi‑Payload Systems

Researchers are already stacking different drugs inside one capsule, each with its own trigger. One could deliver an anti‑inflammatory first, then a regenerative molecule later—perfect for chronic diseases that need staged treatment.

Beyond Medicine

While our focus is health, the same technology could power agriculture (targeted pesticide release) or environmental cleanup (smart encapsulated enzymes). The possibilities are as big as our imagination.

Potential Research Questions

- Can programmable microcapsules fully replace traditional booster shots?

- What is the maximum payload size a PDMS‑TMPTMA capsule can hold without compromising burst reliability?

- How does temperature‑triggered release compare with pH‑triggered release in the gastrointestinal tract?

Wrapping It All Up

Programmable microcapsules are more than a clever lab trick; they’re a gateway to safer, smarter, and more convenient healthcare. From a single‑shot vaccine that frees you from multiple clinic visits, to a malaria vaccine that stays stable in the heat of the tropics, the technology promises to boost immunization coverage worldwide. By marrying material science, microfluidic engineering, and a deep understanding of the body’s own signals, these tiny capsules bring us a step closer to truly personalized medicine.

What do you think about a future where your medication knows exactly when and where to act? Have you ever taken a vaccine that felt like a “miracle” because you only needed one dose? I’d love to hear your thoughts—feel free to share your experiences or questions. Together, we can keep the conversation rolling and stay ahead of the next breakthrough.

Leave a Reply

You must be logged in to post a comment.